VALVE ADJUSTMENT

should work perfectly), Screwdriver, Sandpaper (400 and

600 grit), Notepad, Needlenose Pliers, Feeler Gauges (down

to at least .0015"), Flat Piece of Glass, Gaskets, and Shims

bike and could cause severe injury in the event of a crash. If you are at all unsure of your ability to perform

this procedure correctly, PLEASE do not attempt to do so.

have a shop manual on hand, and consult as many sources as possible before undertaking this job. I take no

responsibility if you damage your engine using this method. The methods for checking and adjusting valve

clearance on a 4v motor may vary at certain points, and I don't know where because I have never seen the

innards of a 4v motor.

Be sure to visit the links section, where I have links to other great valve articles.

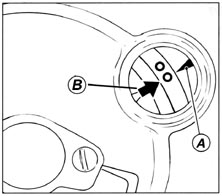

the SOHC, 2-valve,

desmodromic valve actuation

system:

1. Opening (upper) rocker arm

2. Opening shim

3. Split rings (also called

retaining or half rings)

4. Closing shim

5. Closing rocker return spring

(takes the minute amount of

slack out of the rocker)

6. Closing (lower) rocker arm

7. Camshaft

8. Valve

A= Opener clearance

B= Closer clearance

as the dealer would have you believe. You just need time, patience, the right tools, and an attention to detail. Before you

start, don't assume that it is a one-day-type job (unless your dealer is really good and carries a stock of shims). I broke it

up into two days for checking/one day for changing, but it should only take a slow person (like myself) about six or seven

hours for disassembly, checking, changing, and reassembly if you can find the shim right away. I had to wait because my

dealer didn't have the shim (but that's better than waiting a month for an adjustment appointment). I get frustrated

easily, especially when my bike is out in the hot sun and I'm trying to reassemble it, which is why I broke it up into so

many parts.

measuring the opener and closer shims), a feeler gauge that goes down

to at least .0015" (for measuring clearance), a screwdriver, new gaskets

for the valve covers (not absolutely necessary, but cheap insurance),

the shims you will replace, a piece of glass or very flat object, 400 and

600 grit sandpaper, a clean work area, fuel filter, timing belts, and

spark plugs if you want to replace them, and a lot of patience and time

set aside. You also need a basic set of metric tools. If you need to

measure the closer shim, you will also need a piece of metal stock to

help you. See Chris Kelley's Ducati page for more detailed info on that,

and see below for pictures of the shim in action.

before removing the tank. (Supersports will require removal

of the rear shock) With the PCV hoses gone I had ample

room to work without removing the tank- crank breather

tube removal has definite advantages. The only thing I had

to do on mine was remove the battery and push back my box.

Take the belt covers, valve covers, and oil cooler off and place

the bike on a rearstand. If you have the stock battery box

you can still access the front vertical cover by taking out the

battery and pushing the rubber tray out of the way.

plugs. You need to remove the plugs so the engine can turn over

easier when trying to find Top Dead Center. This is a good time to

clean or replace the old ones.

rear wheel. Take a jack, then place a piece of wood or similar

extension on the jack pad. Place the extension directly under the

front center of the swingarm, as shown. Then have a buddy sit on the

bike with his hand on the brake and holding it steady. Then, jack

the bike up and place jackstands under the swingarm on each side.

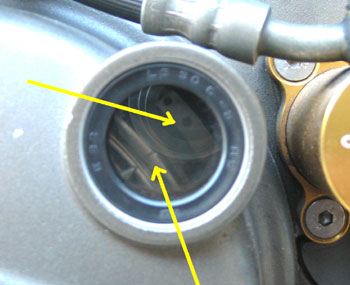

wheel while watching through the sight glass. Again, it's

impossible to get a good picture through that glass, but this is

what you are looking for. You want the arrow to line up with

the tickmark on the bottom half. It's much easier to see in

person. You need to spin the wheel very slowly, and it takes

some coordination to line up the ticks in the window exactly

because the engine rotates faster than the tire. Give it small

nudges, and it should be easy to line up then.

finding TDC. There is an arrow on the bottom left corner of the

sight glass, towards the front. This lines up with a tick mark on the

front portion of the flywheel. There is also an arrow in the upper

right corner, towards the back. This lines up with a dot on the back

(deep) part of the internal spinning piece. I just added the picture

below to show the two dots and arrow in the back a lot better, but it

doesn't show the front portion with the tickmark- confused yet?

They line up at the same time. When you find this mark, only one

of the cylinders is at TDC- you'll need to check the clearances of

each cylinder's valves to find out which one. When you spin it

around again and line them up, the other cylinder is at TDC. At

TDC, the valves are both closed and the piston is at the top of the

cylinder. Another helpful aid is that the horizontal cylinder has a

dot on the cam spinning gear that lines up with a raised nub on the

black rubber portion on the horizontal head when it is at TDC. One

more thing to throw you off- there are two TDC's per cycle on a 4

stroke engine, and the one at the end of the compression stroke is

the one you should measure on. The tick mark on the horizontal

cylinder cam gear that I was talking about may seem like it is at

TDC, but may actually be at the wrong TDC. Before messing with a

certain valve shim, ALWAYS stick a screwdriver in the cylinder to

verify that the piston is there (you'll be able to feel the top of it) and

that the shim gaps are roughly equal. At BDC or the TDC on the

exhaust stroke, the measurements may be close enough to fool you,

but they'll throw you off. So make sure it's TDC on the

compression when you measure.

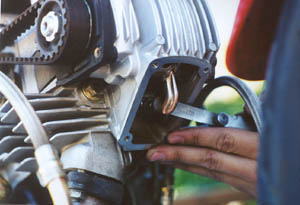

covers removed. This is what you're looking at. You may note

that I never said to remove the belt covers. Some articles say

you need to, but I found it unnecessary, unless you want to

adjust your belt tension while you're at it (which I didn't). It's

just easier to leave them on until you need to take them off.

take slack out of the spring. Then measure this clearance again.

It should be larger than the one before. In this case, it was .005".

This is also called the "loaded gap". This is where it gets tricky.

Take that measurement and subtract the first one (the opener

clearance) from that. That will give you your closer clearance, in

this case .0015". Consulting my clearance chart (below), you will

see that the opener is too tight (by.0005" at least), and the closer is

"too loose". However, in talking with many valve afficianados, I

have heard that the closers should not be worried about until they

hit at least .002", and can go up to .004" on a 2v (this is very

extreme and everybody uses different limits). As I have been told,

it is better to err on the loose side, which brings me to the opener

being too tight. This is caused by the valve wearing into it's seat

and pushing it further into the head, and hence further into the

rocker arm.

between the rocker arm and the opener shim. What feeling are

you looking for? The best way I have had it described to me is as

the way it feels if you stick the gauge in a phonebook. Try it-

you'll see that it goes in and out easily. You don't want snug or

hard resistance, that means it is too big. It should glide in and

out, but should still touch the surfaces on both sides. You'll just

have to try it and see. The vertical exhaust opener clearance

measured .0035". This clearance that you measured is the

opening shim's clearance, and doesn't need to be added or

subtracted from anything. This is also called the "unloaded gap".

clearance on the intake valve (oops), but it's the same method as

the exhaust opener. This shot is of checking the closer clearance

on the intake valve, which was .0015 as well. The intake valve is

the valve on the side with the intake runner from the carb (black

valve stem seal). The exhaust valve is on the exhaust pipe side of

the head (green valve stem seal).

easier access here. You will need to move the oil

cooler out of the way, though.

cylinder on TDC. This one measured .0045", too

loose. This will require ordering a thicker shim to

reduce clearance.

one was .006", meaning the closer was

at .0015". Nothing to worry about yet.

Definitely too tight. This one will either require a new shim or

can be filed down to increase clearance, which is what I did.

You may also notice I went back on what I said about taking

off the belt covers. Hey- it was my first time and I didn't

know any better!

one was within spec at .0015".

within spec? You will need to remove the shims and measure them, using

those measurements as the basis for the new shim sizes (or how much you

will need to file the old ones down). Because my closers were all OK, I

didn't need to remove them, but that is only one more step once you have

the opener shims off (see below for more info). To remove the opener

shim, you must first remove the clip that holds the rocker arm in place.

Be sure when re-installing the clip that there is still the washer on each

side of the clip as before.

opening shim off of the valve.

do this, though, you must slightly rotate the engine to relieve pressure

on the rocker arm (actually I rotated it a lot, but everything I've read

says that it's only "slightly"). You're trying to get the cam to move

out of the way and let the rocker slide over. The intakes are hard

because by the time the cam is out of the way, the intake valve is

halfway through it's cycle. You can slide the rocker off, but you must

push the valve down to get the rocker to go back in it's original

position. Whatever you do, DON'T force anything. You could end up

breaking a very important piece in the valvetrain. If something seems

jammed, don't keep spinning the motor. Stop and evaluate exactly

what is causing the jam and try to reverse what caused it. I used the

rear wheel to do this. If you do remove the closer shim, it will allow

the valve to fall down, so you can't use the rear wheel method for

removing the closer, because the valve will fall into the cylinder,

leading to all kinds of trouble. If you need to remove the closer shims

to measure them, you can remove the timing belt and turn the cam

independently from the crankshaft, but be sure to stick something

like a screwdriver into the spark plug hole to keep the valve from

falling in.

measured .138". This was the loose one, so I needed to get a shim

that was .0015" thicker to match the other intake opener (.0035",

which is right on according to the intake opener specs). To find out

which shim from Ducati is .139", you must convert that to

millimeters- .1395" converts to an off number of millimeters, and

Ducati sells shims in sizes every .05 millimeters. The closest size

to the one I needed was 3.55mm, which converts to .13976". That

means it was thicker than needed, but I was going file it down

slightly. Also note- measure the shims before you leave the

dealer. They'll look at you funny, but you can't trust the marking

on the package (my supposed .13976" shim was actually .141",

luckily it was thicker so I could file it down).

openers, because they were too tight. To file them down, I wet

sanded them on the flattest piece of glass I could find using 400 grit

paper, then polished them off with 600 grit. I would measure them

every thirty seconds or so with the micrometer, and when they

were close to the necessary size, I would put them in, re-install the

rocker, and measure clearance again at TDC. This requires the

time and patience that I mentioned earlier. After all, if you're not

going to do it right, why do it? It's also hard this way because you

may oversand and it will be too loose, but remember that it is OK

to err slightly on the loose side. You could also just order a close

size from Ducati, erring on the loose side. But this may make it

too loose (by .002" or more), so I just decided to sand them down.

likely it will be too loose, rather than too tight. You will need to get a tighter shim. But, how do you get it off? I

don't have pictures, but I can try to describe it. Once you have the opener shim off, you can start. First, secure the

valve below the rocker with something such as vicegrips or wire to prevent it from falling into the cylinder (which it

will want to do when the shim is removed). Now, rotate the crankshaft to allow you to push down on the closing

rocker (the lower one) and then push down on the closer shim to reveal the half/hale/split rings. You can then

remove the half rings that secure the shim using a magnet. A perfect pic of this is located in the article about valve

adjustment here. Now slide the shim off and measure it. It's really only one more step, but I didn't do it so I don't

have pictures. Also, with the opening rocker pushed over combined with trying to spin the crankshaft to allow you to

push down on the closing rocker, be ABSOLUTELY carfeul to avoid binding the opening rocker and the camshaft. For

detailed pictures of the closing shim removal/measuring, Chris Kelley's Ducati Tech is an excellent resource.

loose. Everything goes together easier, except the fuel lines (if you took the tank off). Be absolutely sure

that the lines don't get kinked when the tank is lowered. The fuel line should go back in a loop underneath

the tank mounting pad. It also may be a good idea to order some new valve cover gaskets for the

re-assembly. I replaced mine because I didn't want to worry about them, but the old ones were still good. If

you have any questions, feel free to e-mail me, and I'll be glad to help as much as I can. Good luck, and

remember to take your time and feel comfortable with the process before starting.

hurt to keep them on the high side (.004" for the intake openers, .005" for the exhaust openers, and .001" for the

closers). A clearance of .000" is possible, but very hard to obtain. .000" is a condition where there is no difference

between the loaded and unloaded gap. You cannot fit a feeler gauge in between the closing rocker (bottom) and the

closer shim, but can still turn the closer shim with your finger.

Intake openers: .003"-.004"

Exhaust openers: .004"-.005"

Intake closers: .000"-.001"

Exhaust closers: .000"-.001"

NOTE: 4v motors have a whole different set of clearances, on the looser side of the 2v. I am only listing them here as

reference.

Intake openers: .003"-.005"

Exhaust openers: .005"-.007"

Intake closers: .000"-.004"

Exhaust closers: .000"-.004"

views expressed herein are those of myself and do not reflect those of Ducati or its affiliates. The "DUCATI" logo and "Circle D" are

registered trademarks of Ducati Motor Holding, S.p.A., all other content on this website is copyright 2006, Monster Man Productions.