CLUTCH SLAVE CYLINDER

Tubing, Container, Lots of Towels, Rubber Mallet, Brake Fluid

(DOT 4 or 5.1, but NOT 5)

Ducatis are by no means known for their

reliability or ease of pull. Thankfully,

one of the few aftermarket parts readily

available for a Ducati is the clutch slave

cylinder. Two big names in the industry

are Yoyodyne (sp?) and Evoluzione.

After researching both and asking for

opinions, I purchased the Evoluzione unit.

cylinder for a better bleed (the master cylinder doesn't have the banjo bolt/bleeder screw combo). So, it worked out

OK.

leak-free warranty. It was also significantly cheaper than the Yoyodyne, but received just as many favorable reviews.

Plus I got a free banjo bolt. I'll take this space to plug Evoluzione Cyclesports- I had very good luck with them. The

customer service was excellent, I received my order in two days, and the prices were good. Back to the slave cylinder.

The installation was well-outlined in the instructions included, but I'll go ahead and skim over it in the following

section. The first step in installing it is to cover the entire bike with rags. Brake fluid is extremely corrosive to

finished surfaces. If you get any fluid on the paint (or anything else for that matter), immediately wash the area with

soap and water. It only takes seconds to leave a permanent mark!

Ducati with the master cylinder/reservoir/lever in one

piece, not the remote reservoir system. However, the

rest of the process is very similar, so read on. You don't

need to worry about working quickly to avoid getting air

in the system- the second it sucks any amount of air you

are in trouble, so just take your time. First (with bike

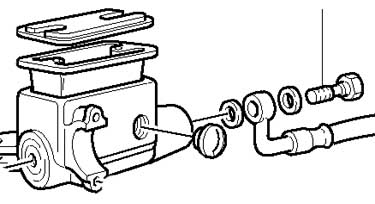

covered) unscrew the banjo bolt holding the brake line at

the master cylinder. Next, screw the bleeder banjo bolt

in place of the plain banjo bolt, being sure to use the

supplied crush washers. Do not overtighten, simply snug

it up tight. Leave the bleeder fitting screwed in until

later.

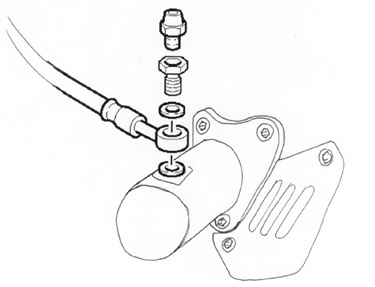

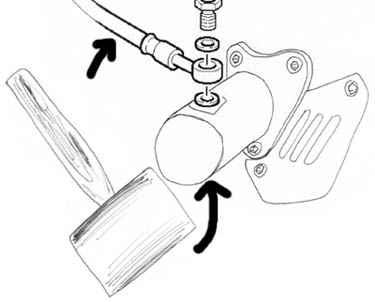

cover on. Next, unscrew the three bolts holding the

old slave cylinder in place. Pull the master cylinder

and accordian seal off of the clutch actuation rod.

You can let the slave cylinder hang there, just be

sure not to pump the clutch lever.

cylinder and pull the line off. Put the new crush

washer on the new slave cylinder, then the clutch

line, then the crush washer, then finally the

bleeder banjo bolt. Again, do not overtighten (i.e.

wrench it hard. It only needs to be tight enough

not to vibrate loose).

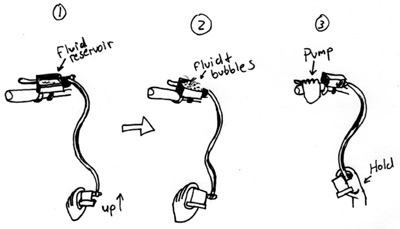

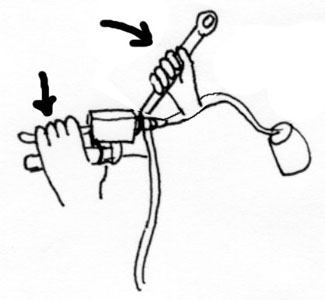

there is air in it. The very first step is to do

something called 'reverse bleeding'. This is done

with the slave cylinder hanging there. With the lid

on the master cylinder (it doesn't HAVE to be on, it

just prevents a stream of fluid from shooting ten

feet in the air) you hold the slave cylinder in your

hands, with the outside facing up. Then take your

finger and push the piston inside as far into the

slave cylinder as you can. A bunch of bubbles and

fluid should come out into the master cylinder

reservoir. You will need to then pump up the

handle (slowly, with the reservoir covered to

prevent a jet of fluid) a bunch of times to get fluid

back down into the slave cylinder.

BE VERY CAREFUL WHEN DOING THIS. If you

pump too much (it takes a LOT of pumping when

there is still air in the system) the piston could

shoot out of the slave cylinder and you will have to

start all over again. So, while pumping the handle,

check that the piston isn't about to reach the end of

the slave cylinder. The more you pump and push,

the less air wil be in the system and the further the

piston will travel with each pump. By the time you

pump it four or five times and you can feel the

piston travel pretty far and there are no air bubbles

coming into the master cylinder reservoir (only

fluid) you should be ready for a regular bleed.

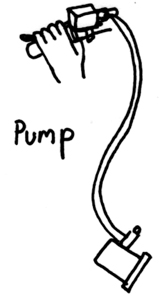

are level, and the reservoir is full. As you bleed, fluid will be used up and you

need to keep adding it. If it gets too low, air will enter the system.

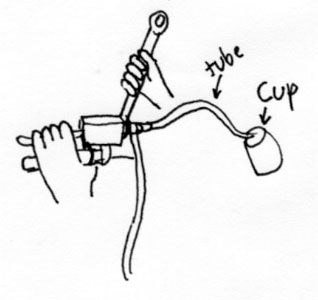

screw nipple, and put the end in a cup or something similar.

Put the end wrench on the bleeder screw. Pump the handle

several times, and while slightly applying pressure, unscrew

the bleeder screw from the bleeder banjo bolt you just

installed, and continue through the stroke

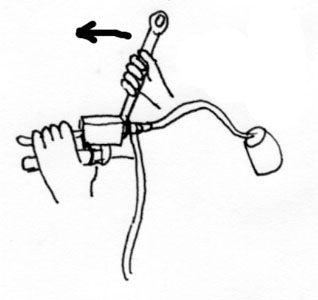

near the end of the stroke,

tighten the bleeder screw

and release the handle. DO

NOT RELEASE THE

HANDLE UNTIL BLEEDER

SCREW IS TIGHT! The only

time the bleeder screw

should be open is when you

are pulling on the handle,

and slowly. Do not pump the

handle when the screw is

open, because every time the

handle is released it sucks

fluid (and the air in the

fluid) back inside. You must

repeat this until you see no

air bubbles coming out with

the fluid.

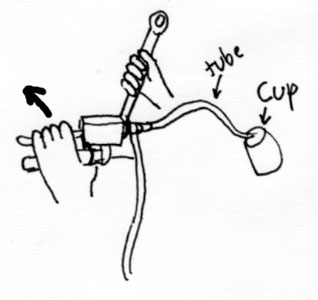

was pulling in the clutch lever, then holding it and at the

same time realeasing the bleeder screw. The springs in

the clutch pack will force the piston back in it's bore, but

since the screw is open, the fluid will take the path of

least resistance and essentially bleed for you. Once the

fluid stops flowing, tighten the screw, then pull in the

handle and hold it again, then realease the bleeder

screw, etc. With this method I was able to get a little

better bleed than before, so you may want to try it out.

I would throw in the occasional reverse bleed from before. This isn't absolutely necessary, and it requires more dexterity

to assure that the piston doesn't shoot out of the slave cylinder. I prefer to do this so that I know there is no air being

trapped.

You can now switch to the bottom fitting and repeat the entire process again. All of the above steps are applied to the

bleeder screw on the slave cylinder. You can bleed the bottom screw with the slave off the bike, because most of the

pressure will be directed out of the bleeder screw. Just be extra careful when pumping the handle that the piston doesn't

shoot out. After you have bled the top and bottom, you need to tap the slave cylinder and fluid line with a mallet to

dislodge any trapped air bubbles.

again. Simply bleed the top and bottom

bleeder screws again to make sure there is

NO air. After that, you can install the old

slave cylinder. Clean off the clutch rod,

and apply some high temp grease. Be sure

to read the instructions of whatever slave

cylinder you are installing and get all the

required parts in there (seals and stuff).

Put some Loc-Tite on the bolts and simply

snug them up. Then install the sprocket

cover.

If it doesn't work properly (i.e. no neutral finding at stops, no gear shifting at stops,

hard shifting, etc.), then the most likely cause is still air in the system.

Try bleeding again. If that doesn't work, here are some more suggestions:

When I bled mine, I waited a week and bled it again, only to find an air bubble at the top and bottom. Same

thing when I bled it two weeks later. Air bubbles will lodge in the lines and then surface later.

piston inside. To adjust it, the slave cylinder needs to come off. Once it's off, remove the master cylinder reservoir

cover. Using the reverse bleeding technique, push the piston in the slave cylinder and notice that fluid comes out.

Now screw the screw clockwise about a 1/4 turn. Push on the piston again. If fluid still comes into the reservoir,

screw the screw in again, and so on until you can't push the piston in with your fingers (i.e. no fluid can travel back

into the reservoir with you pushing on the piston). Next, back it out 1/2 turn. Push on the piston again to make sure

fluid travels back into the reservoir, and you're set. What happens if you screw the screw all the way in, but can still

push fluid back in (and can't get neutral when stopped)? That's what happened to me, and some people suggested that

I get an adjustable clutch lever from another model Ducati. I haven't done that yet, but I am sure it will work.

slave cylinder piston to increase the travel of

the rod, but am very hesitant about doing that.

are those of myself and do not reflect those of Ducati or its affiliates. The "DUCATI" logo and "Circle D" are registered trademarks of Ducati Motor

Holding, S.p.A., all other content on this website is copyright 2002, Monster Man Productions. If you would like to link to my page, feel free to do so. If

you would like to use the pictures or text on your own page, please e-mail me, or at least give me credit and install a link to this web page.