RELOCATION BRACKET

MAKING YOUR OWN BRACKET ON THE CHEAP

AND LOOKING GOOD DOING IT

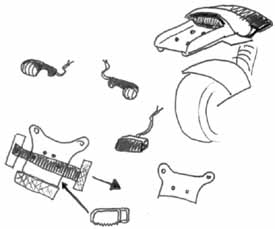

Wrench, 4mm and 5mm Allen Wrenches, 20ga. Sheet Steel,

Hammers, Flat Black Paint, Primer, Sandpaper, Rivet Gun

inches of overhang cut off

already!

1. Rubber mallet

2. 22 gauge sheet steel, about 12x18". Available at Home Depot or

similar.

3. Electric or pneumatic grinder with thin cutting wheel.

4. Electric drill and various drill bits.

5. A block of wood with a hard edge.

6. 8 thin flat washers, 4 lock washers for the long screws on the back,

and four or more nylon washers in metric size to fit the four screws.

7. Various zip ties.

8. Primer and paint. I used an epoxy primer and flat epoxy enamel for

durability.

9. Sandpaper.

10. Rivet gun and two rivets (not absolutely necessary)

won't go into an explanation of how to do that because it's very simple.

The wires are also hard to mix up in case you forget where they went.

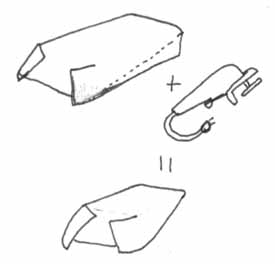

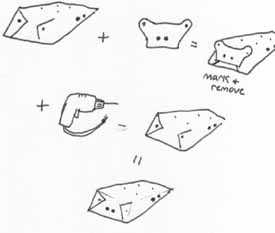

The only part that requires work here is to cut off the existing

reflector/bracket area that extends below the license plate. The

previous owner had already done that on mine. If you don't like the

idea of cutting stock pieces (which I wouldn't have done), you can bolt

the license plate directly to the bracket you make, instead of bolting

the bracket to the bracket you make. You'll end up with the license

plate bracket, two signals, and the license plate light.

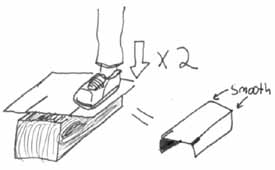

of the bike, as far back as it will go and still remain level with the

black plastic piece. Then mark on the sheet two lines, which is where

you will bend the bracket down on each side. You want the bends to

be inside the frame, so that it will be flush with the black plastic piece

on top and will bolt easily to it with the four screws. Still confused?

The two tubes of the frame are not flush with the black plastic piece

from the top. You want the bracket to be flush with that, so the bends

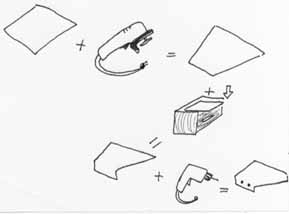

for the edges need to be inside the frame rails. Once marked, cut the

grooves along the lines just until the cuts go under the cover of the

black plastic piece. You'll end up lopping off the rear of your bracket

in the end for fine tuning, so you just want the general area.

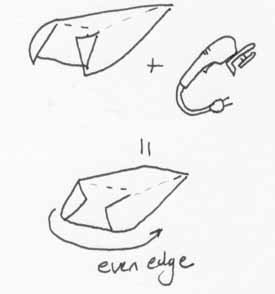

you made, and bend it down on one side. Now, do the other side.

You don't want a hard edge, but I said to use a hard edge block of

wood. That's just cause it's easier to line up with. Once the bend

has started, you can finish it by hand. If you really want to get

fancy, you can bend it over a steel pipe or something.

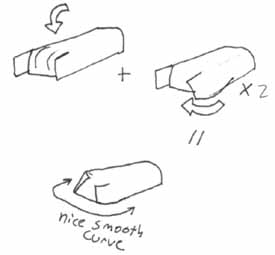

to, as shown. This is angled downward, not straight down. You can

see from my picture that the plate is at an angle. Now, you will bend

the sides around. This is done by hand and again, not straight down.

It will be wide at he front and narrow at the rear, and have a nice slow

curve going around each side. The sides are angled downwards

instead of straight down.

top of the front, going forward. This will make it look like a

lopsided pyramid from 3D view, but a wedge from the side.

down further than the rear tab for the plate. This is where you will

cut the edges even with one another, and make the edge continuous

all the way around.

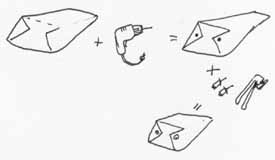

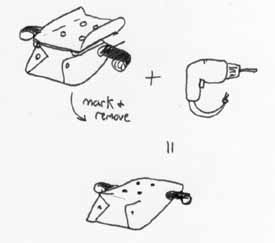

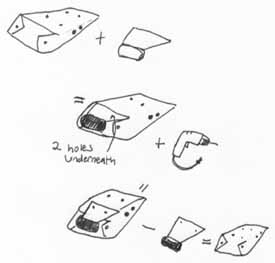

underneath on each side. These are for the rivets that will secure

them together to prevent vibration and rattling. Now use the rivet

gun to pop the rivets in. If you don't have a rivet gun, you can

simply use a nut and bolt with a lock washer.

bracket down and cut off however much you need to off the rear.

Stick the license plate bracket, license plate, and license plate light

up underneath the black plastic piece with the bracket in place and

see how much you need to cut off the rear. Once you get that done,

you can put it all back in place and see where the best place for the

turn signals are. I mounted mine as far forward as I could. Keep in

mind, the lock button for the seat gives you an inch less room going

backward than the other side, so mark that first. Then drill the

holes for the bolt and wires, and mount them. They probably won't

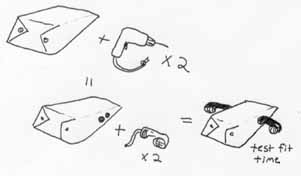

be even at this point, but you should put the bracket up under with

the signals on, test to see that everything fits up under the black

plastic still, and bend each side of the bracket so that it is even. DO

NOT PULL ON THE SIGNALS TO BEND THE BRACKET. They are

not as strong as steel and will break. Just hold the bracket and

push on the sides of the steel until it's straight.

and mark through the top where the four holes are. Before you drill,

make sure that the signals don't hit the frame, and that the license

plate light still fits up under the black plastic. Then take it off and

drill it. Then mount it in place and check for fit. Fine-tune all the

angles and make sure they are straight. My turn signals are actually

angled down and forward slightly.

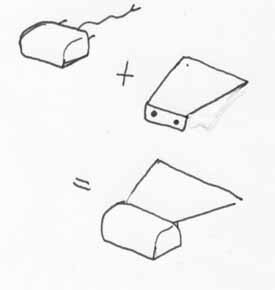

steel you cut off the

back of the bracket to

make the license plate

light holder bracket.

It needs to be a wedge

type shape as shown.

The small end should

be just wide enough so

that the two bolts

coming out of the back

can go through and be

secured. Mark and

drill those holes. Then

bend it at a 90 degree

angle about a half inch

above that. Now

mount the light on the

bracket. With the

plate/signal bracket up

in the

underneath, between the bracket and the black plastic piece. The two

holes at the front (of the bike) will be uncovered, but now the two

rear most hole will be blocked by the new bracket. Get it straight

underneath and mark and drill the holes.

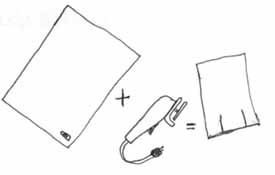

license plate and bracket where they will be on the

new bracket and mark and drill the holes in the

bracket.

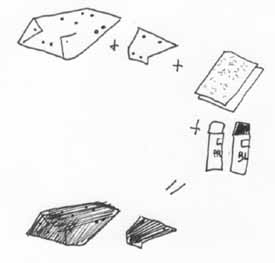

all the bare metal with a rough grit paper then smooth it with a

fine grit. After that, prime it with the epoxy primer. Let that dry

and then hit it with the flat epoxy black. The flat looks exactly

like the black plastic on the bike. Now for the last of the drilling.

You need to drill two small holes about a half inch apart. Send

one of the long zip ties up through the hole, and down through the

other.

it into place with the lockwashers and nylon nuts. Plug the wires into

their original sockets and zip tie the entire mass with the zip tie that

is waiting there. Make sure no wires are hanging down. If I left

anything out, it must not have been important. Make sure everything

is tight and that there is no interference anywhere. Test the signals

for proper operation and adjust as necessary. Enjoy!

are those of myself and do not reflect those of Ducati or its affiliates. The "DUCATI" logo and "Circle D" are registered trademarks of Ducati Motor Holding,

S.p.A., all other content on this website is copyright 2006, Monster Man Productions.