could be harmful to your bike and could cause severe injury in the event of a

crash. If you are at all unsure of your ability to perform this procedure correctly,

PLEASE do not attempt to do so.

one prepared. As you can see, the garage is

clean and I have all my tools laid out along

with my service manual. I even bought one

of those roller seats because I knew I would

be spending a lot of time down low and I

hate rolling in the dirt. Familiarize yourself

with the procedure before you begin.

the little stuff to get to this point. I put her up

on a rear stand, stuck her in 5th, removed the

plugs, removed the side covers, and turned the

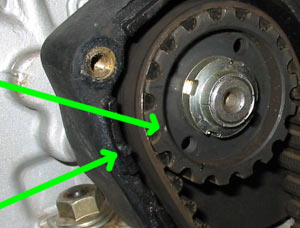

rear wheel by hand until the tick mark on the

flywheel (other side of engine through site

glass) lined up with the arrow (see picture).

At this point, the tick marks on the three gears

should line up......

gear will align with a raised nub on the

rubber portion of the cover mount.

the horizontal cylinder cam gear will align with a raised nub on the rubber portion of the cover mount

as well. All three of these points, plus the tick mark on the flywheel, should all line up together at TDC

on the horizontal cylinder. You want to be at this point before removing the belts. If you don't have an

indicator on each of the three gears, make on on the one that's missing it (i.e., take a paint marker or

something and mark a fixed point.

worry about the gears getting out of alignment since the horizontal is easy to move back into position since

there is no tension on it from a spring (but don't get wacky and try to spin it all the way around! ;)

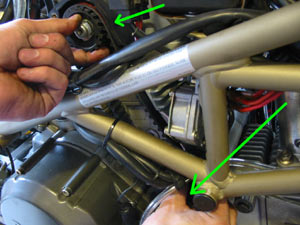

and pop off the belt. The cam gear has a bit of tension

on it that when nudged it will shoot either to the right or

left. In other words, it does not want to stay in one

spot and that makes it hard to get the belt on without

moving a tooth. But it's not near as tricky as I thought

it would be. So, while holding the cam gear in place by

hand with the nub and dot lined up, slide the belt on

starting at the bottom, then top, then bottom, then top.

It's easy enough to do that without getting off a tooth.

I have the rocker cover off just so I could see

what's up. I was a little confused at first because

I thought it should have tension on it, but

everything checked out so don't worry about that.

when the tensioner is on, the gears line up better

with their reference marks, and you'll easily be

able to tell if they are off one tooth.

make sure it's in the right spot. You don't want

to see the results of a belt that's off any amount.

tension, I just ran it around a couple times

using the rear wheel to check for any binding I

may have missed. Everything checked out

fine, so it was time to torque.

I torqued my roller tensioner bolts to 25Nm (after

setting tension of course).

a carbed bike it takes a bit to start since the bowls may have dried from cranking it). I took her for a ride

and got it good and hot, then checked tension, then let it cool, and checked again. You'll notice after a

couple heat-cool cycles the belts will loosen, so you'll need to re-tension a little later. After that they seem

to be good (I left my inspection covers off for a while to keep an eye on them). Easy, huh? I wish I'd

have done it sooner!

and views expressed herein are those of myself and do not reflect those of Ducati or its affiliates. The "DUCATI" logo and

"Circle D" are registered trademarks of Ducati Motor Holding, S.p.A., all other content on this website is copyright 2006 DESMO.